SEALEXCEL INDIA P.LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to SEALEXCEL INDIA P.LTD.

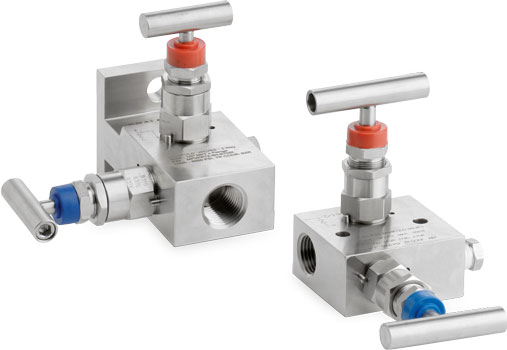

Check Valves

Every unit, fitting and valve has an important role to play in an industrial setting, and if even one unit lacks in quality or precision, it can pose a great risk to the smooth efficiency and safety of the operating environment. That is why, we at Sealexcel offer you precision quality check valves and other industrial units which ensure durability and service at all times.

We have been serving as check valve manufacturers and suppliers for decades in the industry and offer our standard quality products for a range of applications. We never compromise on quality and only offer units which are a source of pride, manufactured as per the state of the art design and updated features.

If you want reliable products for industrial use, Sealexcel is the one you can trust!

Key Features of Our Stainless Steel Check Valve

Our products are unique and in accordance with the stringent quality standards as dictated by the ISO 9001:2008 standard procedures. We ensure compliance at all levels, and are check valve suppliers who manufacture products which are duly checked in specific lab testing facilities, before being supplied to customers. The key features of our instrumentation check valves are,

Units come with a heat code traceable option which ensures certification of material test report.

Each valve unit is subject to stringent lab testing procedures before supply to customers for use in industrial setting.

The units are available in a wide and useful variety of end configurations, which include the male/female NPT, the BSPP pipe connection,Well-Lok tube fittings and the BSPT.

The check valves are designed with a range of strict operating parameters which include a pressure system rating of up to 3000 PSIG. This is 205 bar at the CWP.

The temperature rating of the check valves as per its operating parameters includes up to 198OC, along with the Viton® O Ring.

The units are available in a SS316 material, with wetted parts that are designed in accordance with the NACE MR01-75.

The check valve units have been designed to withstand a cracking pressure of about 1 to around 25 PSIG.

The units have been designed with an instant shut off feature in any upstream condition.

These non return check valves are designed for use in a variety of industrial settings and environments, which include options like liquid, gas and fluid system handling. Choose the Sealexcel check valves to ensure the safety of your system cylinders, and also maintain gas quality during changeovers. Click here to browse through our end connection and check valve dimension options details.

You can also look through our high pressure check valve catalogue to choose the unit you need.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.